Building hardware remotely

Flame and I go way back — all the way to our Prezi days, where we both worked as designers. Somewhere during a meeting we came up with “shmøergh” — the perfect name for a fake nordic design company.

Naturally this name was just a joke. We know absolutely nothing about nordic languages and since then we’ve learnt “shmøergh” is a complete butchering of any real word. But as with any great fake company that doesn’t even have a product, we did the most important thing first: designing the logo. With half of the work done, we just needed 10 years — and snap 💥 now we're building synths under the silly name Shmøergh.

I’m getting a bit nostalgic here, but this really was a long time ago. We’ve known each other so long it feels like we’re high school friends.

Anyway — what I really wanted to talk about is how we actually work on these synths.

Shmøergh is a passion project

Shmøergh has always been a 100% passion project. We both have families and full-time jobs: I lead design at Ghost, Flame is a design manager at LastPass. So how much time we can dedicate to synth stuff is… let’s say “variable.”

The past ~6 months I was deep in Ghost 6.0 (check it out, it's fucking amazing), Flame’s building a house, so it’s been a lot. But we didn’t want to pause Shmøergh completely, so we decided to not start something completely new but remix the already-working Hog synth into a modular cousin — the Hog Moduleur (yes, it’s fake French, there's a pattern here).

We also don’t live in the same city, and okay, Hungary isn’t exactly huge, but it’s enough of a distance to make prototyping and hardware be challenging.

So: limited time, distance, life chaos. How do we make hardware in all that?

Our meticulously improvised process

The way we divide work happened organically. We’re both designers, but I’m an electrical engineer by education, and Flame has a background in physical product design. So naturally – while we both work on design – I take care of electronics, and Flame handles the enclosure, manufacturing, and production.

The process goes something like this:

We start with an idea (The Wall-Sized-Brown-Sound-Megabass-Synth™ is still on the list.)

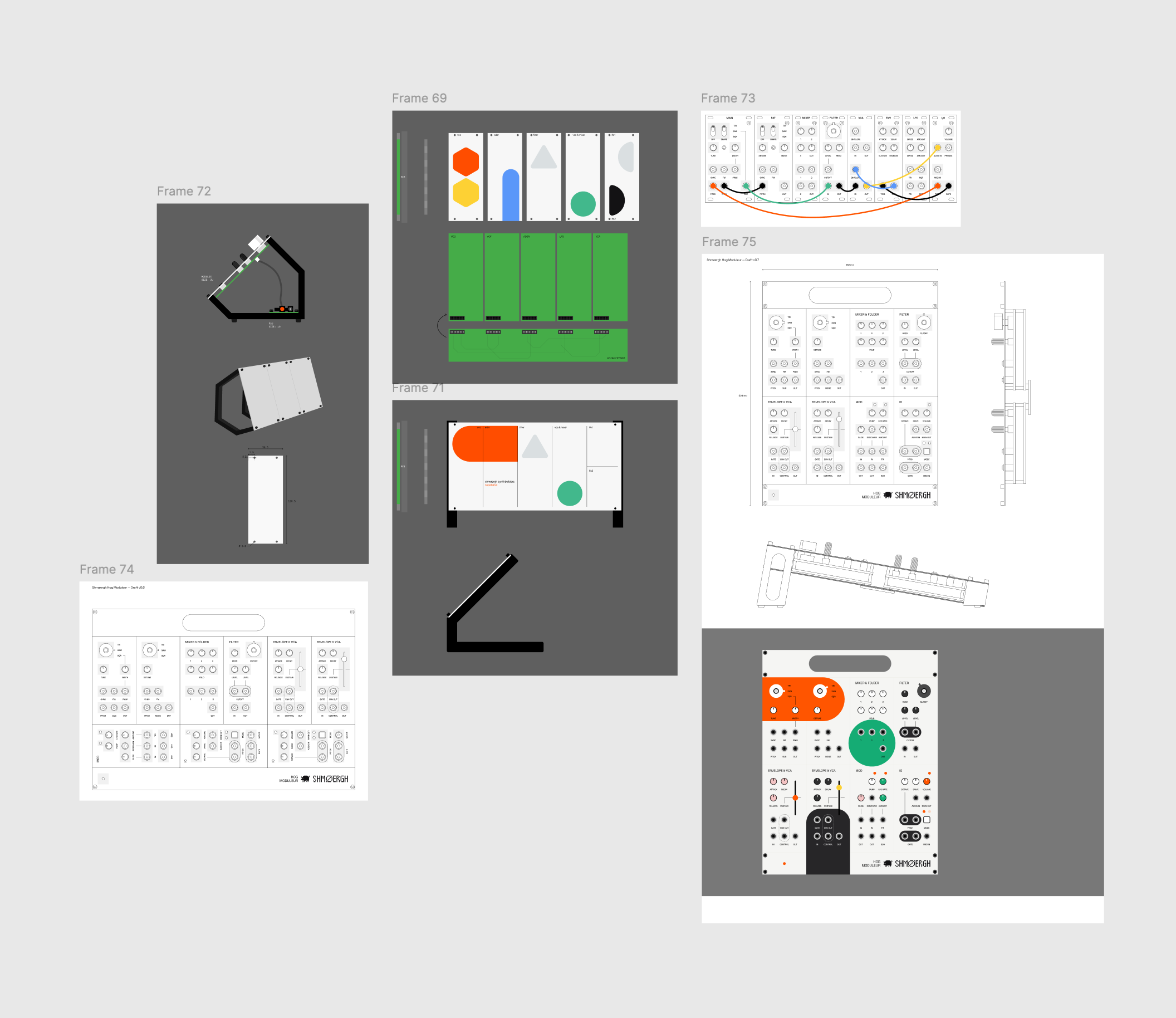

Usually I sketch the design concept in Figma — At this point, I’m not even thinking about feasibility — it’s just about getting the vibe and layout right.

We define the core features — That's best done in person. If we think something would be useful or fun for us, we assume others might enjoy it too. And if not… that’s alright. We are design geniuses after all.

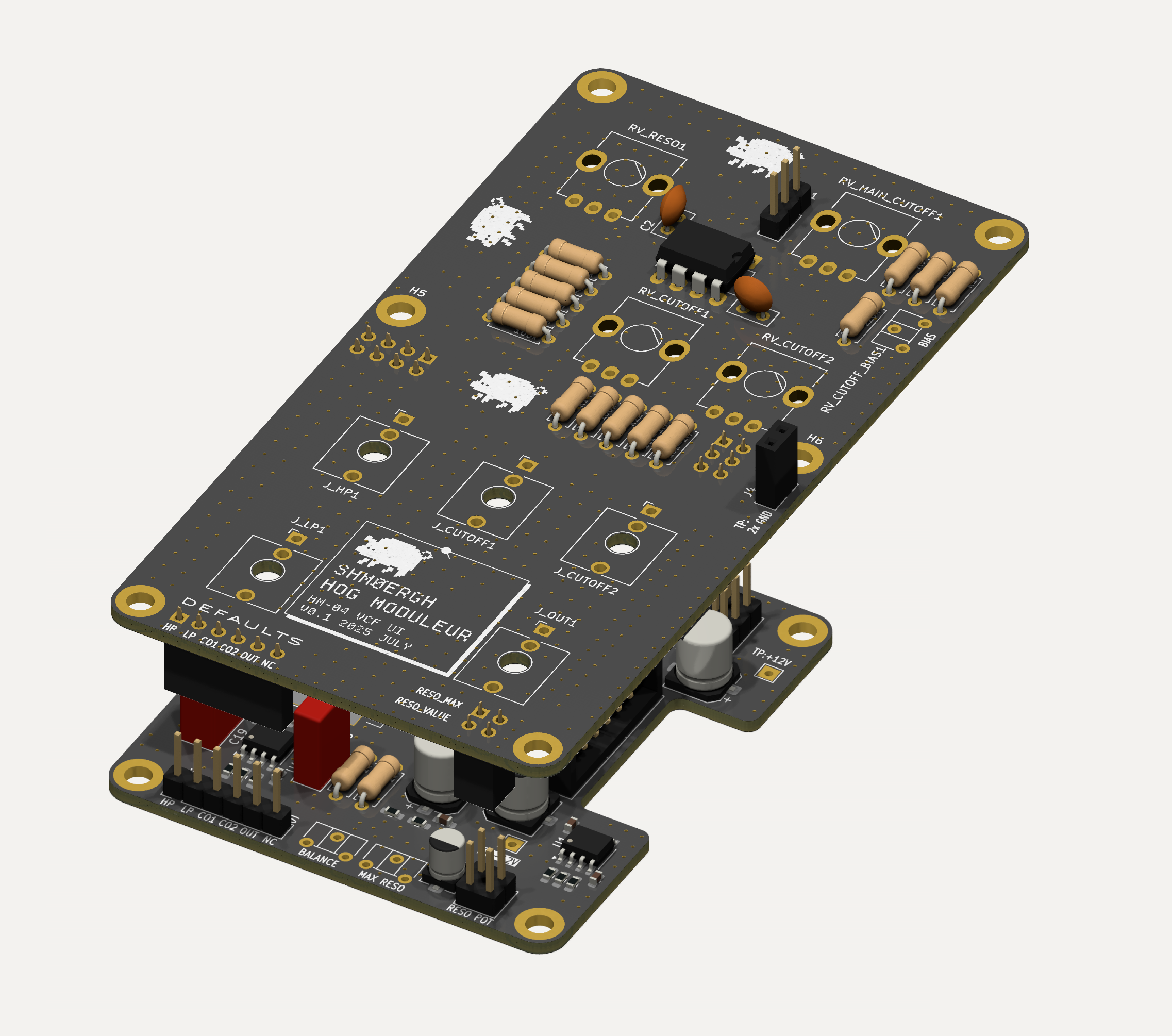

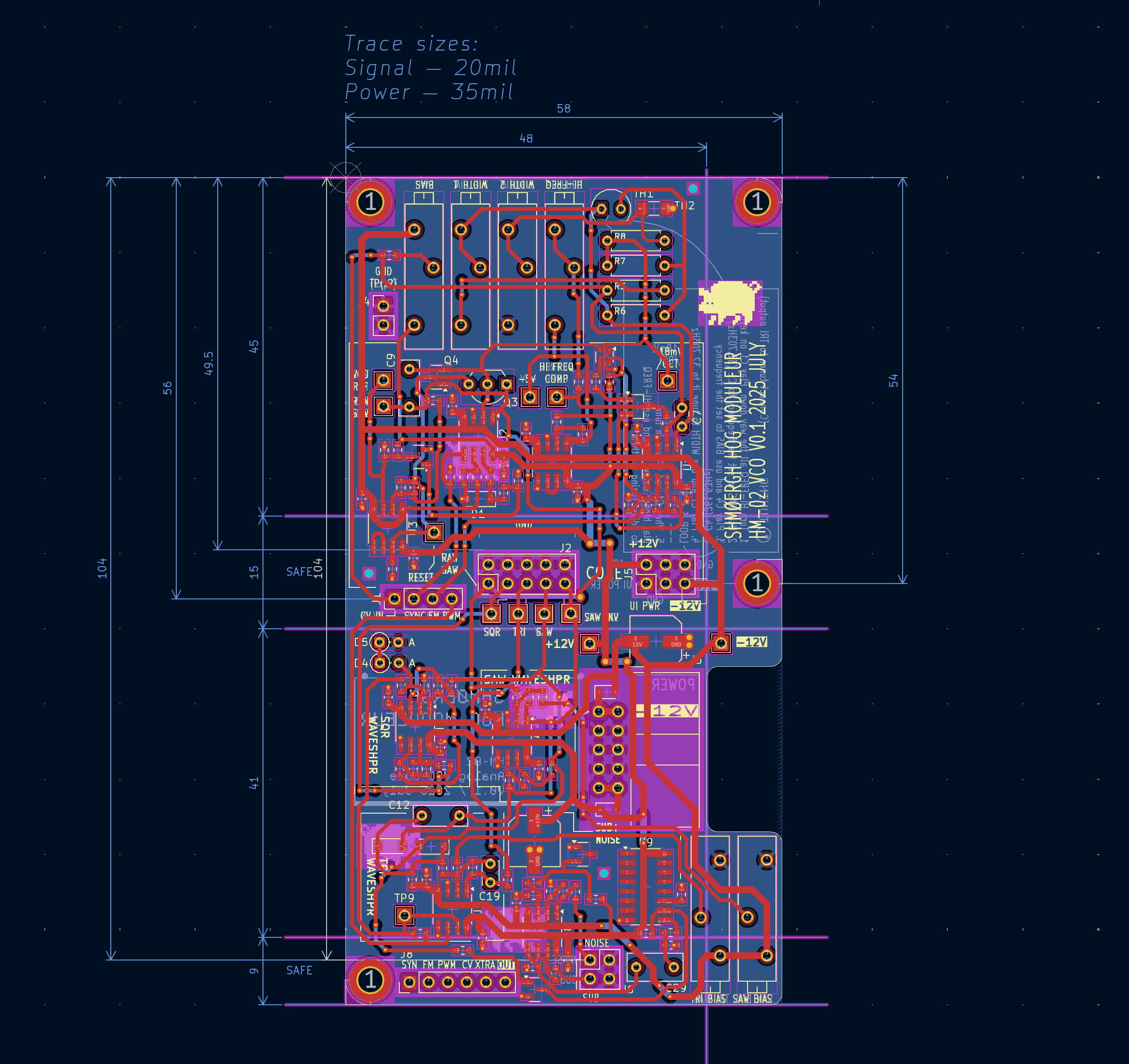

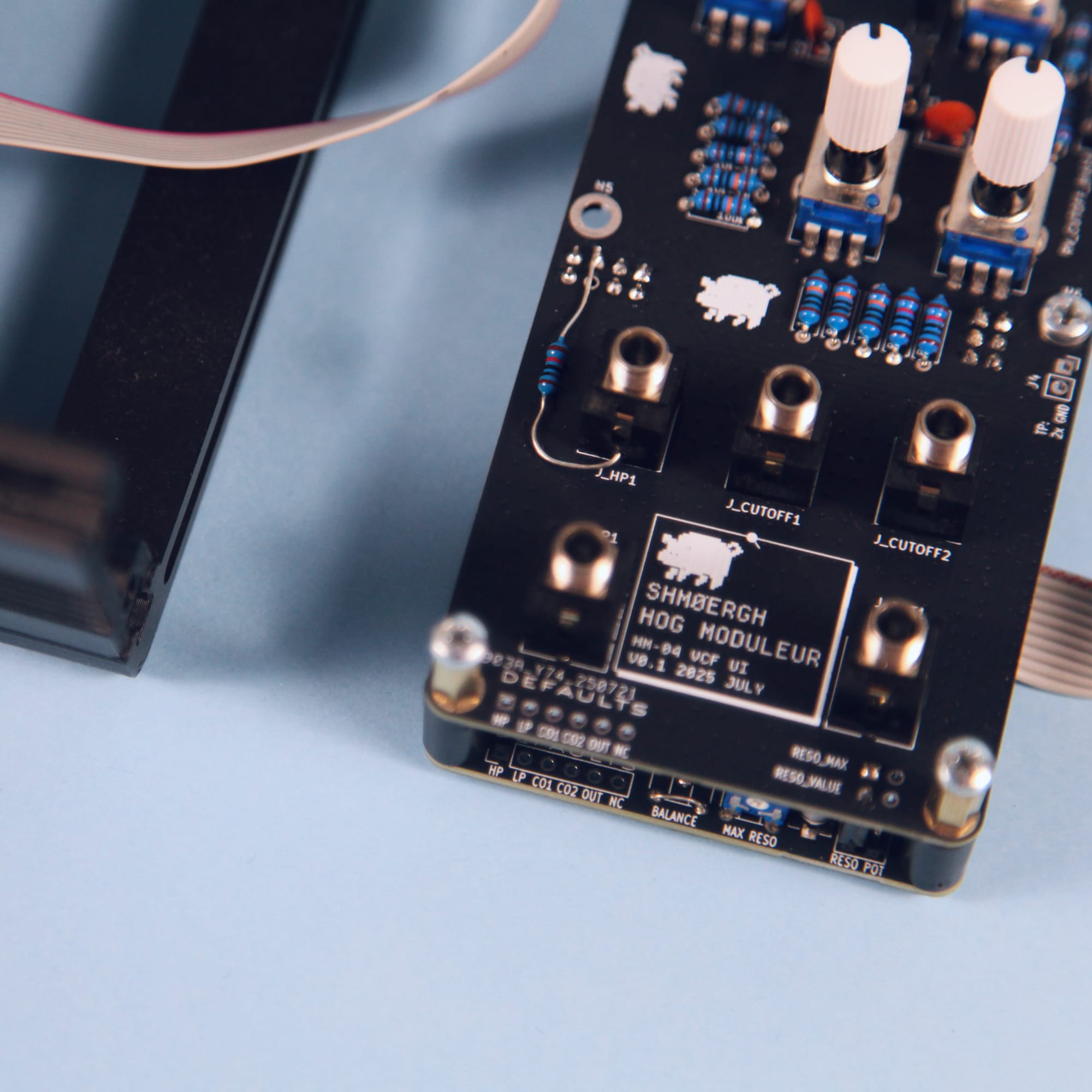

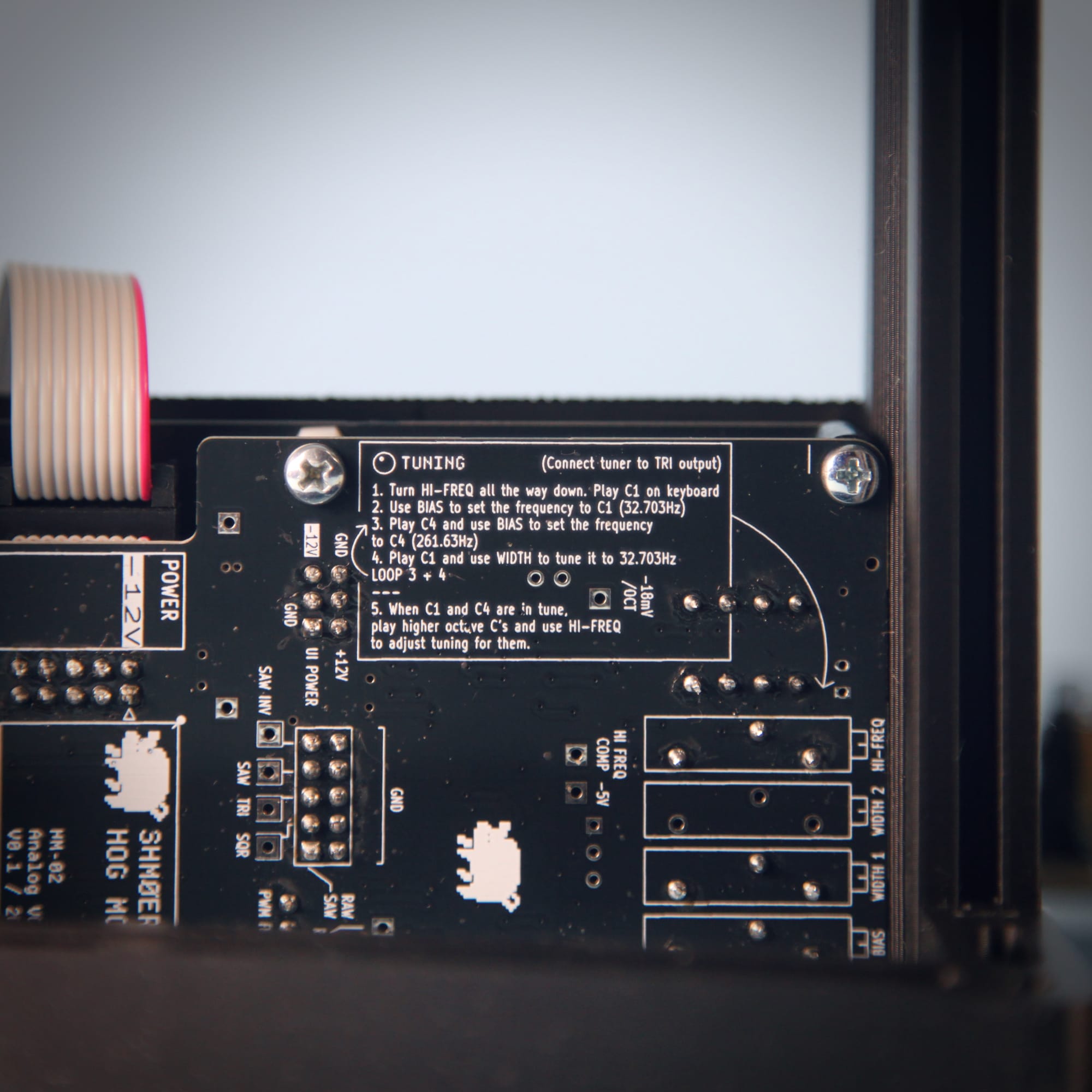

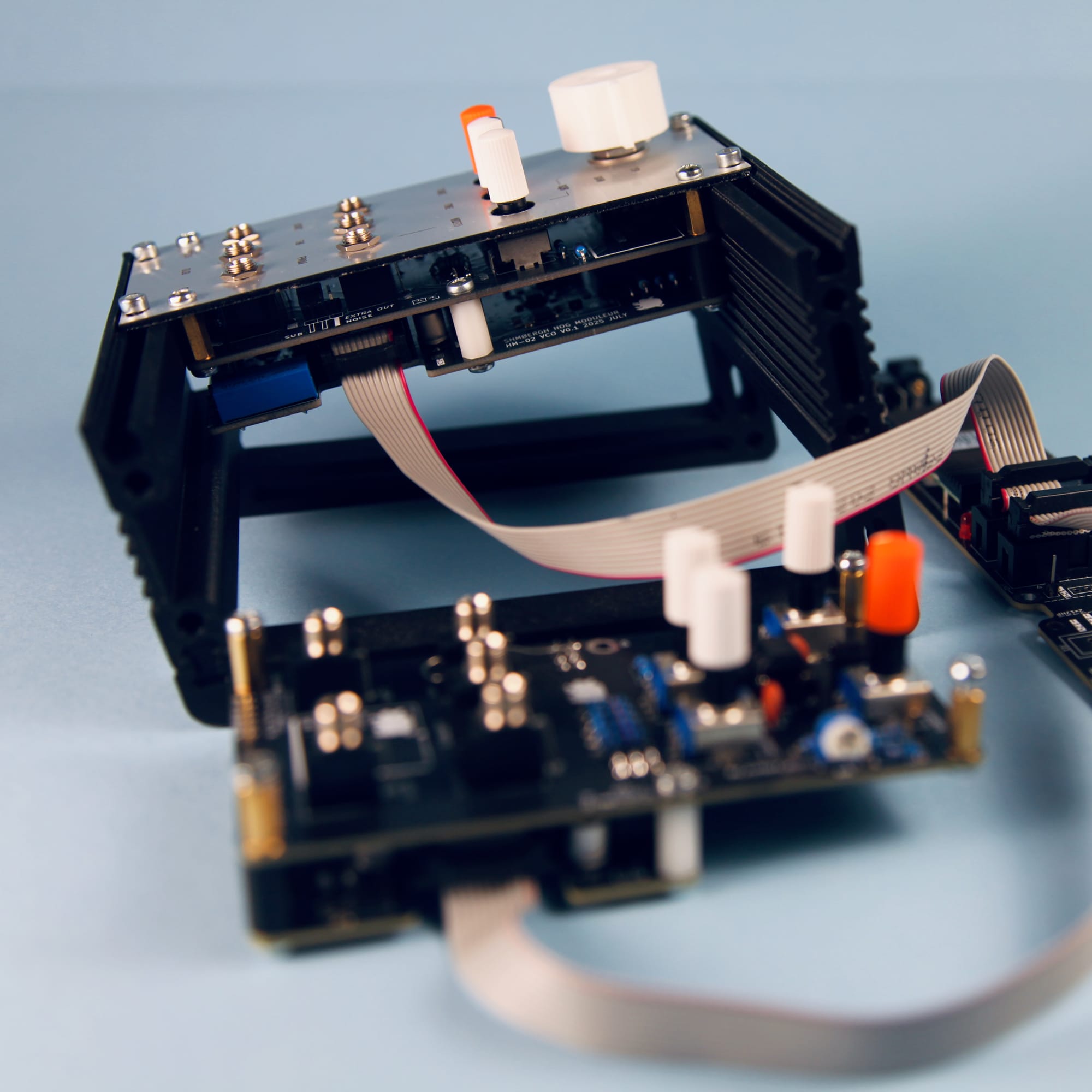

Electronics reality check — Once we know what we want, I figure out what’s actually possible. Components need to be widely available, the PCB size has limits, and we’re almost always working in 3D with stacked boards. Each Hog Moduleur module, for example, has two layers: the bottom contains the core circuitry — oscillator, wave shapers, etc., while the top holds the UI elements — jacks, knobs, switches, buttons.

Flame designs the physical thing — While I’m deep in circuit design, Flame is exploring materials and working on the mechanical and enclosure details. There’s a ton of back-and-forth between us, we're refining things bit by bit until everything clicks in place.

We build a few prototypes — PCB design rule #1: your first version is never perfect. But the prototype lets us test features, size, feel, and share with some friends. The same goes for enclosures. Here is a box of wasted stainless steel that got thoroughly Fucked up by Shmøergh™ for the Hog:

Iterate until it feels right — Once it doesn’t suck, we’re done.

...so far we stopped here with all of our projects. And although we have zero clue about selling stuff, with Hog Moduleur, the goal is to finally get it out of the shed and into the hands of fellow synth weirdos — even if just a few. Stay tuned.

Where we’re at with the Hog Moduleur

Right now, we’re right in the middle of this process with the Hog Moduleur.

We want this synth to be as flexible as possible not only in features but in production too:

- The final version will come in a single enclosure with all modules built in.

- But each module will also be available as a standalone Eurorack version with its own front panel so it can be stuck in any Eurorack system.

- We’re separating the core and UI PCBs so they’re easy to reuse in other projects.

- And everything is open source — so anyone can build along, remix it, or just steal our mistakes.

We already had most of the circuits from the original Hog, so for me the job is “just” redesigning and retracing the PCBs. Which honestly, is quite meditative.

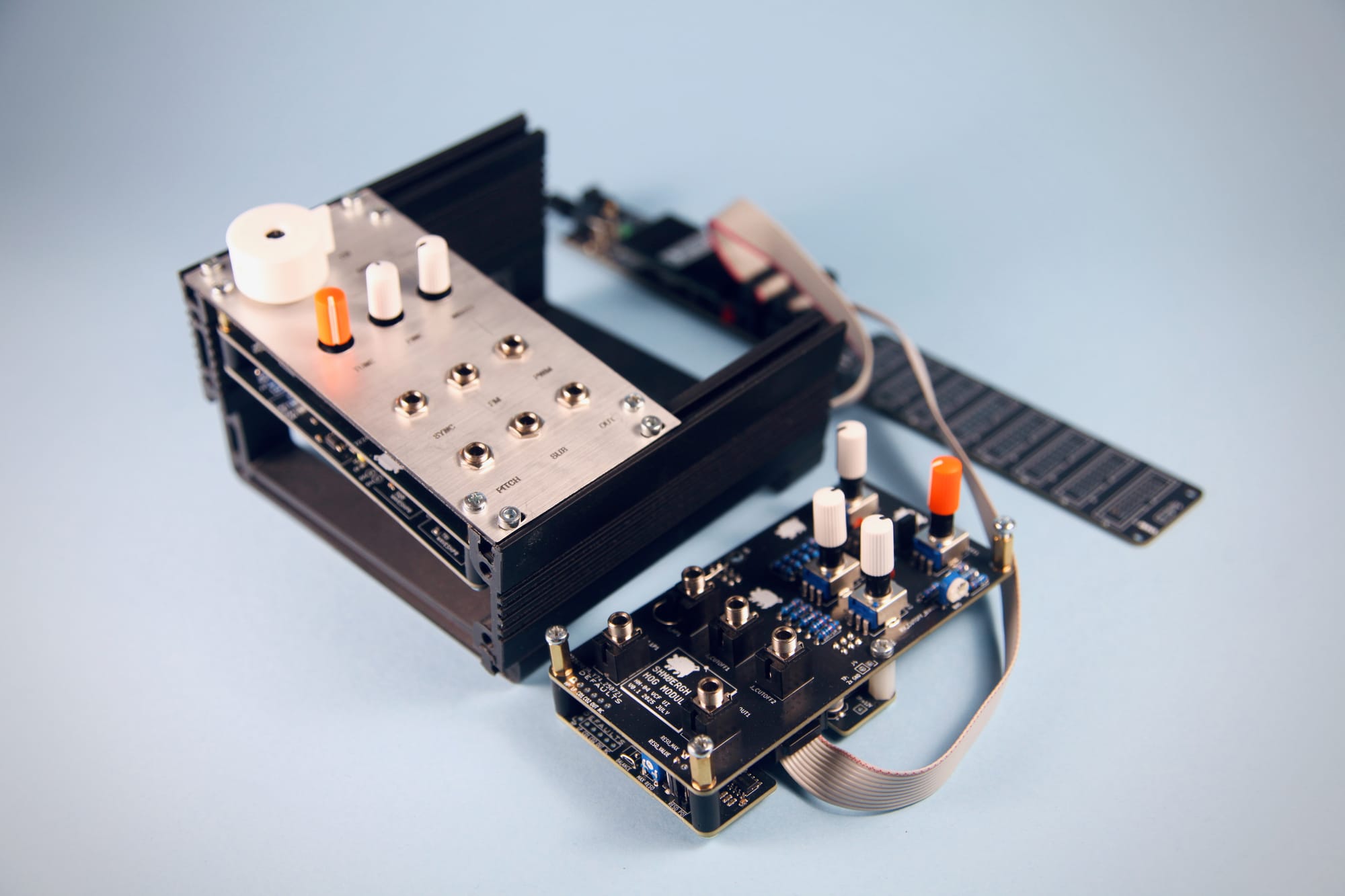

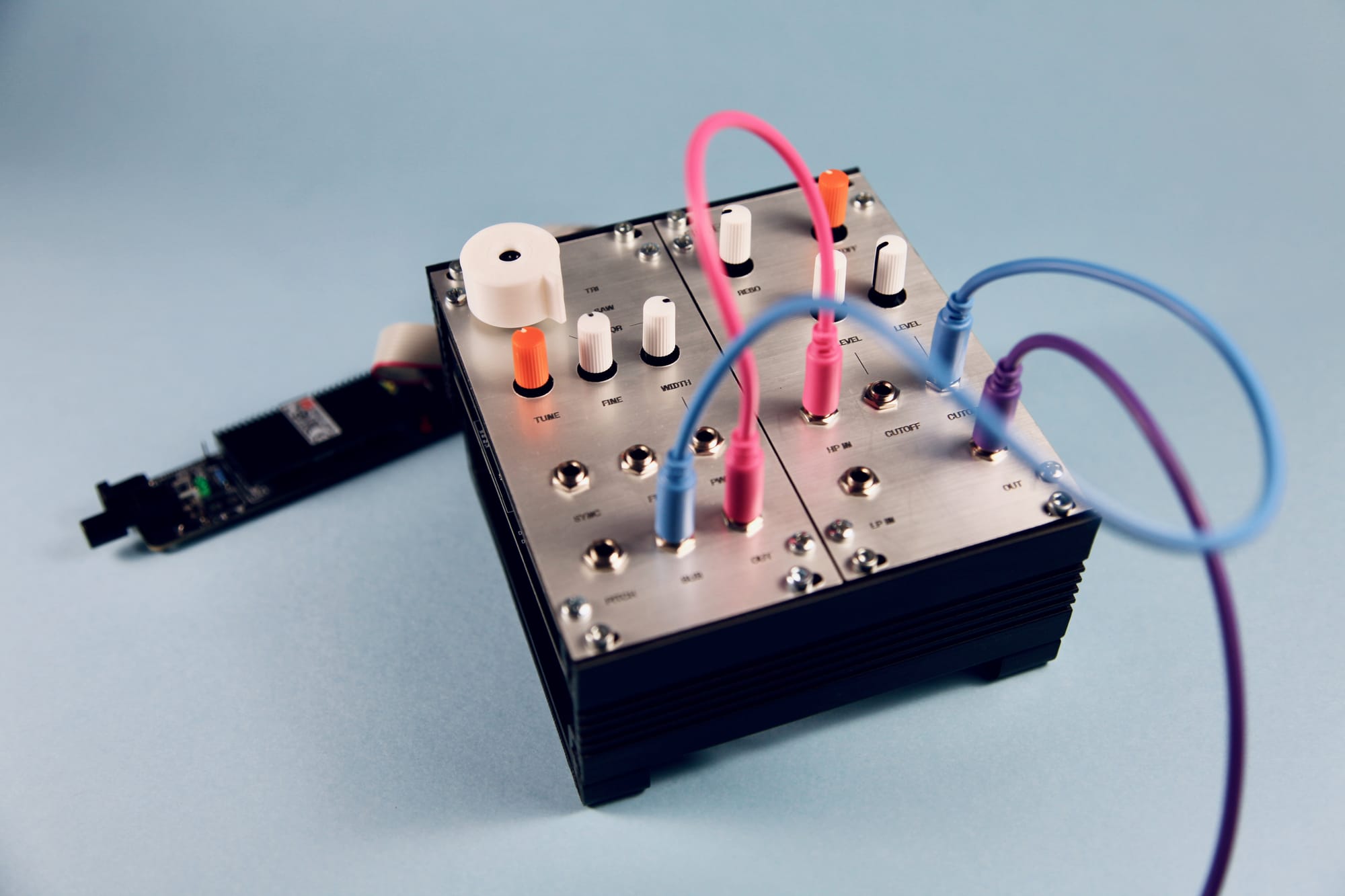

The plan for the Hog Moduleur includes 6 distinct modules (8 in total, plus the power supply), and we’ve already finished and tested the most critical ones: the oscillator and the filter. To play around with them, I designed a temporary, 3D-printable Eurorack rails, and Flame laser-cut some quick plastic panels which he mailed me (yes, in an envelope that the postman put in our mailbox).

It's just two modules yet but already so much fun

The electronics for modules 3 and 4 are in production, just ordered the mixer PCBs from China.

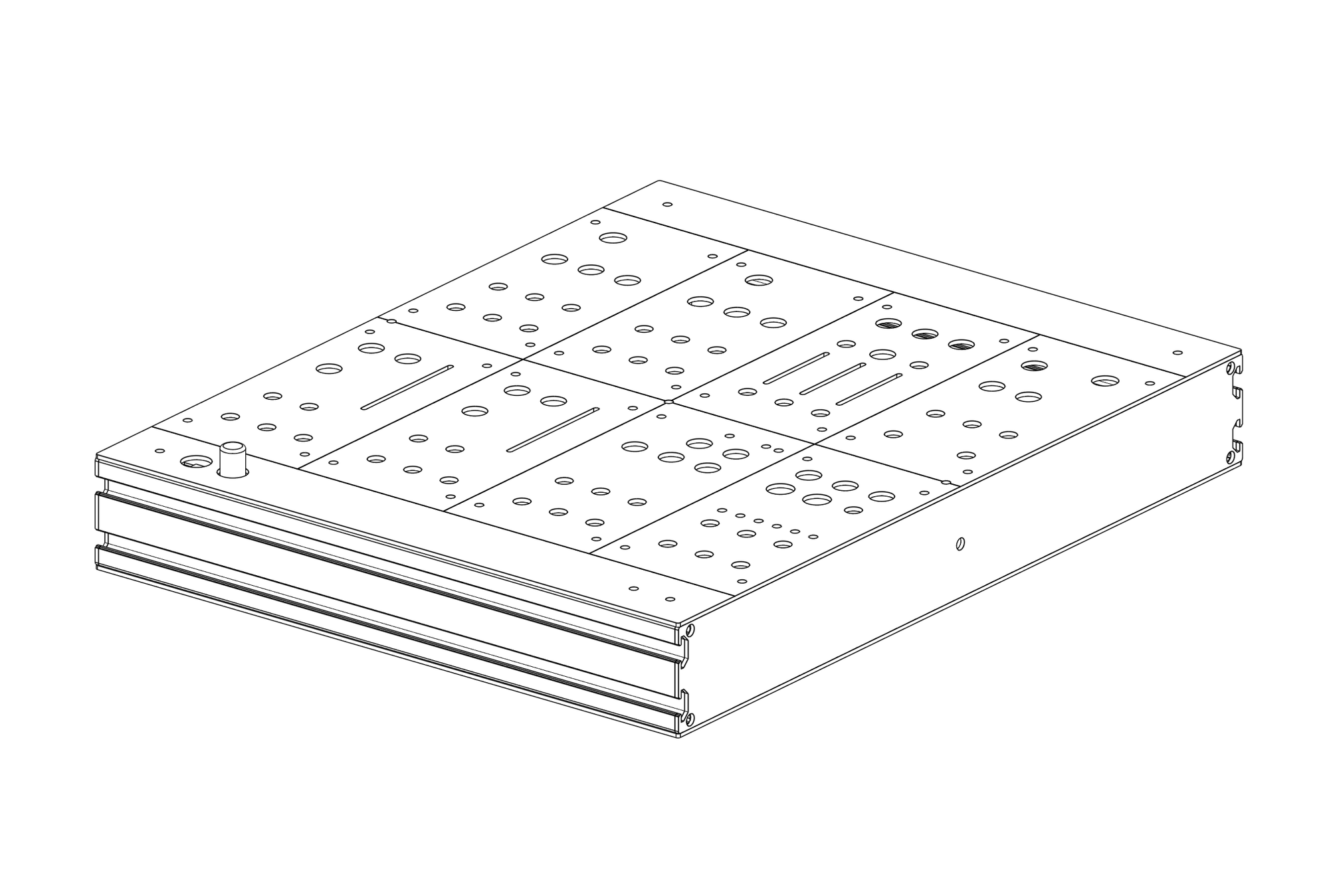

Meanwhile, Flame – 60 km away – is working on the second iteration of the unified enclosure prototype. We're just about to get that cut from aluminum — a material we never worked with before.

First enclosure prototype of the Hog Moduleur laser-cut from plastic — no electronics inside

Oscillator and filter in custom 3D printed Eurorack rails

And that’s where we are: right in the messy, exciting middle.

More soon.

Zimo