Moduleur Build Guide

Just gimme the files

All design files, schematics, Gerbers, BOMs and panel files are available on the Moduleur Github repo:

About the Shmøergh Moduleur

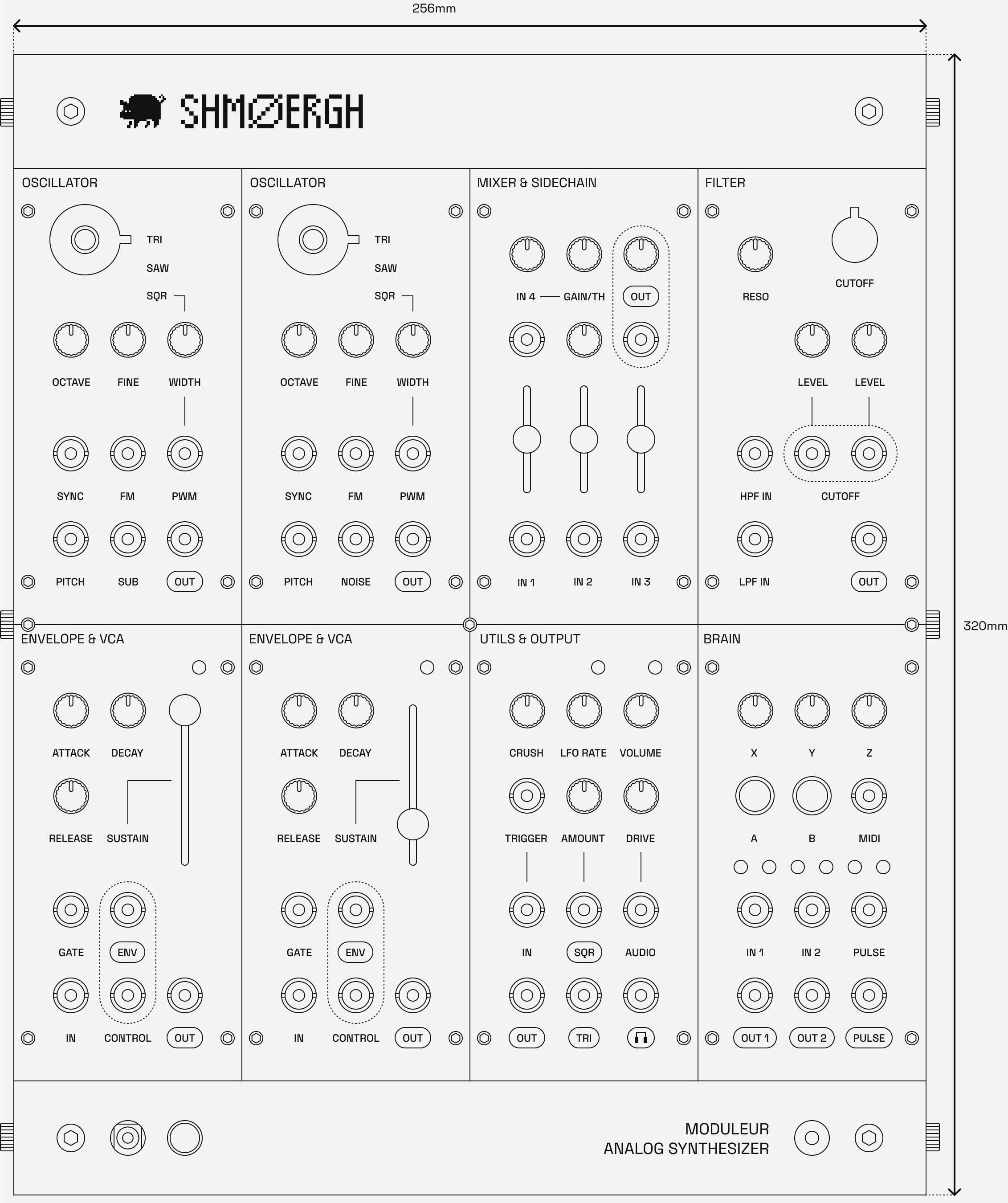

The Shmøergh Moduleur is fully analog, DIY-friendly modular synthesizer system based on the circuit blocks of the original Shmøergh Hog. The instrument is built from discrete modules — oscillators, filters, VCAs, utilities, and a digital “Brain” module — that can be used in a pre-patched configuration or integrated into any Eurorack system.

The project is designed for builders who want a hackable analog instrument. All circuits, PCBs, firmware, and mechanical designs are published in the Moduleur Github repository, including schematics, Gerbers, BOMs, and panel files. Each module is isolated and documented so it can be assembled, modified, or reused independently.

The synth consists of 6 distinct modules (8 modules altogether):

- VCO with triangle, saw, square, sub and noise (2x)

- A mixer with sidechain compressor

- A diode-ladder filter

- A combined ADSR envelope generator and VCA (2x)

- Utils module containing an analog bit crusher, an LFO with square and triangle output and an output interface module with overdrive and headphones output

- An universal digital module called Brain based on a Raspberry Pi Pico or Pico 2

The Moduleur follows standard Eurorack power and signal conventions (±12 V rails with reverse polarity protection, 10-pin power, 1 V/oct VCO tracking). Wherever possible, the designs prioritize robustness, availability of components, and clarity of signal flow over novelty. Simulation files and test notes are included for understanding or extending the circuits.

Full build guide

The complete build guide is available on the Moduleur Github repo: